We have had the opportunity to interview the Oriental Aquarium team located in Singapore

At RAYPA, we want to know how our customers use our media preparators and how our products help them achieve their business goals. On this occasion, we have contacted our customer Oriental Aquarium in Singapore to interview Satwant Kaur and Tessa Hamid, technicians of their micropropagation laboratory. Our aim is to learn about their experience with our AE-MP Series media preparators.

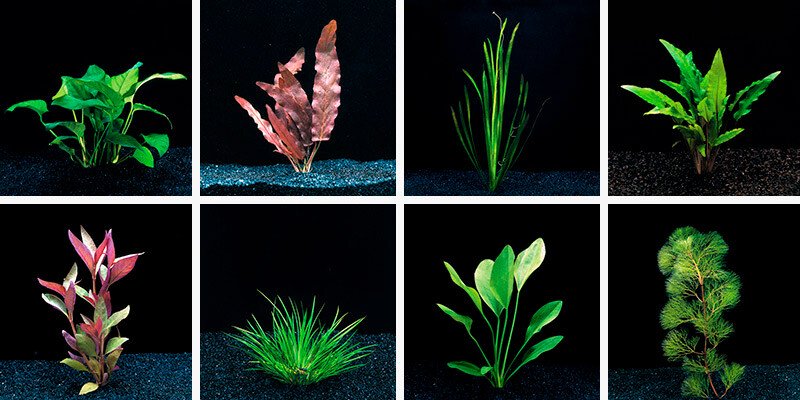

Oriental Aquarium is a company dedicated since 1968 to the production and distribution of products for aquariums, terrariums and ponds. s. It is one of the main suppliers in the industry, serving well-known brands and professional growers. Based in Singapore, the company distributes its products worldwide and has subsidiaries in different regions of Asia, Australia, Europe and the United States of America.

The main focus of the company is to produce and supply aquatic plants cultivated through traditional methods and plant tissue culture. Their product range includes aquarium plants, water lilies, perennial plants, pong plants and other marginal species. The company also operates as a distributor of aquariums accessories, live insects and aquarium plants for retail chains, and provides contract farming services.

Despite the presence of increased competition, Oriental Aquarium has consistently faced numerous challenges over the years, maintaining a strong commitment to continuous improvement, expanding its international presence, increasing its quality standards and looking for innovative solutions.

-

First of all, we would appreciate it if you could explain to us how you use our media preparers in your laboratory.

In our plant tissue culture laboratory at our headquarters in Singapore, media preparators play a crucial role in our daily operations. We use them to prepare large volumes of culture media quickly and efficiently, ensuring that we have an appropriate supply of media for our plant production.

We heavily rely on the 80 and 100-liter models to meet our media preparation needs. The 80-liter model is more frequently used when we need to prepare smaller amounts of media. On the other hand, the 100-liter model is used when we need to prepare large volumes of media.

In general, our laboratory team considers media preparators to be one of the most crucial pieces of equipment in our facilities. They have enabled us to streamline our media preparation process, saving us time and increasing our productivity.

-

Could you provide us with an overview of the various functions your plant tissue culture laboratory performs and how these activities contribute to generating revenue for your company?

Oriental Aquarium is a globally recognized company specialized in the production of a wide range of aquatic plant species. Our company utilizes traditional and modern plant tissue culture methods in our cultivation processes, and this latter approach is carried out in our state-of-the-art plant tissue culture laboratory located in Singapore. This holistic approach enables us to produce and supply a wide variety of aquatic plants suitable for use in both greenhouses and aquariums to other growers and end customers worldwide.

In our plant tissue culture laboratory, we use the media preparator on a daily basis to prepare the necessary culture media for the optimal growth and development of our plants. This process is essential to maintain our strict quality control standards and to achieve a level of quality that would not be possible with traditional cultivation methods. In addition, some plant species that are grown using the plant tissue culture method cannot be grown using other methods.

-

How are these aquatic plants cultivated? Specifically, can you explain the transition process from artificial agar-based soil to terrestrial or aquatic soil?

The process of cultivating these aquatic plants consists of growing them in a container with a semi-solid substrate, composed of agar, as well as various growth regulators, nutrients and other compounds necessary for the optimal growth of the plants. Moreover, sometimes we use the liquid suspension culture method for some species.

During the transition process from artificial agar-based soil to terrestrial soil, it is essential to thoroughly wash the roots to remove any agar residue and prevent any damage to the plant. Once the agar has been completely removed, plants are ready to be planted in the base of the water tank, where they will thrive in their new environment

-

What are the reasons for using the plant tissue culture method for aquatic plant cultivation?

There are several reasons why we chose to use the plant tissue culture method for plant cultivation. Firstly, there is a great demand for in vitro plants and cuttings from other growers who find that it offers numerous advantages compared to traditional methods. In vitro plants do not require atmospheric CO2 control, have lower mortality rates than naturally propagated plants and exhibit more stable and higher quality production. Additionally, some plant species may only be found in nature, and preserving their collection through the production of plant tissue culture is a more sustainable and environmentally friendly approach.

-

What type of media do you prepare? In addition to culture media for plant growth, do you also use the media preparer for other microbiology preparations, such as peptone water or buffer solutions?

No, currently we only use the media preparator to produce culture media for plant micropropagation. We don’t use them for any microbiology application.

At the formulation level, we use different types of media for different groups of plants. The recipe we prepare varies depending on the species and the specifications depend on the requirements of each application.

-

Before obtaining our media preparators, how did you perform these tasks?

In the past, the culture media preparation was a laborious and time-consuming process. We had to rely on jars, baskets and autoclaves to sterilize the 10 and 20-liter containers. This method required many arduous steps and could only produce a maximum of 40 liters of media at a time, using two autoclaves. However, with the incorporation of media preparators in our laboratory, the process has been greatly simplified. Now, with a single equipment, we can automatically prepare up to 90 liters of culture medium, making the process much faster and more efficient.

-

We know that you first purchased the 80 liter media preparer and then made a second purchase of a 100 liter model. Why?

In fact, we initially acquired the 80-liter media preparator and found it to be very valuable in production terms. With this equipment, we were able to generate almost twice as much culture media as we used to produce manually with an autoclave.

Also, we were very satisfied with the experience of daily use of the equipment and the technical service provided by RAYPA. This positive experience encouraged us to invest in a second equipment, the 100-liter model. Our decision was motivated by the need to produce larger volumes of media at a faster pace and to increase the overall production capacity of our laboratory. Having two preparators provides an additional layer of protection against possible equipment failures, ensuring uninterrupted work even if one of the machines requires maintenance or repairs.

-

What is your current daily production of culture media using the media preparator?

Our current production rate using a single media preparator is about 100 liters per day. However, in case of using both media preparators, we could increase our daily production up to 250 liters per day. Generally, we operate two production rotations for each media preparator.

-

What method do you use to dispense the culture media?

We currently use our own external dosing system, which includes four peristaltic pumps synchronized by a single rotor. Before using this system, we sought to validate its compatibility with the media preparator. To achieve this, we sought the help of RAYPA’s engineering department, who conducted exhaustive tests and made the necessary adjustments to the equipment to ensure that the four dispensing lines of our system could be smoothly connected to each peristaltic pump.

Operationally, we always dispense the culture medium inside a laminar flow hood to avoid potential contamination issues.

-

How did you become aware of our media preparators?

We had some experience with previous media preparators, but we decided to look for a new brand that offered higher capacity models. We conducted thorough research to find possible options and we discovered that Gregory Wong from Innospectra was distributing RAYPA media preparators. It was then when we got in touch with him.

-

What were the reasons that led you to choose raypa media preparators?

Due to the limited availability of media preparator suppliers in Singapore, we contacted Gregory Wong to explore our options. After an exhaustive comparison of efficiency, performance, sizes, and prices with other suppliers, we chose RAYPA. I believe we were one of the first companies in Singapore to try RAYPA media preparators. Initially, we encountered some issues, but RAYPA’s prompt response and resolution led us to acquire a second unit.

“Acquiring a media preparator proves to be valuable investment when producing large volumes of culture media”.

Satwant Kaur, laboratory technician at Oriental Aquarium.

-

In your opinion, when do you think it's worth investing in a media preparator instead of using an autoclave?

Purchasing a media preparator proves to be a valuable investment if there is a need to produce large volumes of culture media, as it leads to higher production efficiency. While the cost of acquiring a media preparator can be high, especially in Singapore, considering factors such as transport costs and import charges, the investment is significantly worthwhile in the long term.

Despite the initial cost, the profitability achieved over the years justifies the investment and makes it a prudent choice for companies that require medium to large-scale production of culture media.

-

What aspects of our media preparator do you think could be improved?

One thing that we think would be beneficial, considering that we use our own custom external dosing system with 4 dispensing lines, would be to improve the output valve, as it is currently too narrow for our needs.

With an improvement in this aspect, it would be possible to obtain a higher flow rate of the culture medium during the dispensing phase. While smaller models may not require a larger output valve, we believe it would be necessary for larger capacity models like the ones we use. With a larger output valve, we could dispense more culture medium in less time, allowing us to dispense the same volume in less time. Then, in the long term, the whole system could be faster, which would be very valuable for us.

“RAYPA media preparator is a really easy to use tool. We have found it to be a simple and efficient solution for us.”

Tessa Hamid, Management Associate at Oriental Aquarium.

-

And what about the equipment design?

Your media preparator has proven to be a really user-friendly tool, thanks to its intuitive touchscreen and easy-to-follow steps throughout the entire preparation process. We have found it to be a simple and efficient solution for us. The intuitive user interface has allowed all of our laboratory staff to operate it with ease, resulting in higher production efficiency.

The quality of the culture media produced by the preparators is excellent, which has allowed us to increase our production rate without encountering any issues. Overall, we are very satisfied with the ease of use and the effectiveness of the media preparators and we consider them an indispensable tool for our laboratory operations.

-

The importance of properly cleaning the media preparator after each use cannot be overstated. What do you think about the ease of cleaning the equipment?

When it comes to cleaning, the equipment has its own pre-configured cleaning cycle. We use this cycle daily, before and after each preparation, simply by rinsing the machine with water and then draining the water before running the pre-set cleaning cycle.

While we have found that the preset cleaning cycle is effective for most cleaning situations and that the internal chamber can be easily removed for deeper cleaning, there are times when a more thorough cleaning of the sterilization chamber is required. A possible solution would be that the sterilization chamber could be removed occasionally from the equipment for more thorough cleaning. However, we understand that the sterilization chamber is a highly integrated piece in the construction of the equipment, heavy and voluminous, which makes this task more difficult…

Regarding the dispensing lines, we use a pressurized flow from a water inlet. First, we visually inspect them and then we remove any agar in the tube with soap and water. For the inner tube of the media preparator, we remove it and use a brush to thoroughly clean the inside, ensuring complete removal of any residue.

-

¿How would you describe your experience regarding the aftersales service and technical support provided by raypa?

It has been a satisfying experience because whenever we had any problem, we immediately got in touch with Gregory. We have also had the support of RAYPA’s technical service, which provided us with a direct communication channel for when we needed to contact them, attending us in less than an hour.

Whenever there was a hardware issue, it was usually resolved the following day, allowing us to continue working without significant interruptions. Therefore, we can say that we are very satisfied with the technical support and customer service we have received throughout all this time.

- From RAYPA, we would like to extend a special thanks to the Oriental Aquarium team for their time and for helping us to better understand how they use our equipment. Thank you very much for sharing your experience with us!